Jaltest MHE (Material Handling Equipment) Diagnostic Tool

Warranty handled directly by AsTools

Warranty handled directly by AsTools

We handle warranty cases ourselves, quickly and without the intervention of the manufacturer. Thanks to our own parts inventory and technical expertise, we can usually help you immediately. Only in exceptional cases do we still send the product to the supplier.

2 years warranty on all products

2 years warranty on all products

All our products come with a 2-year factory warranty. This way, you are assured of long-lasting quality and service.

Easy returns via Returnless

Easy returns via Returnless

Returns are easy via Returnless. Register your return online and choose your own shipping method. Return costs are at your own expense.

Professional customer service

Professional customer service

Our experts are ready to help you quickly and professionally, both online and in our physical store. Questions? Feel free to contact us!

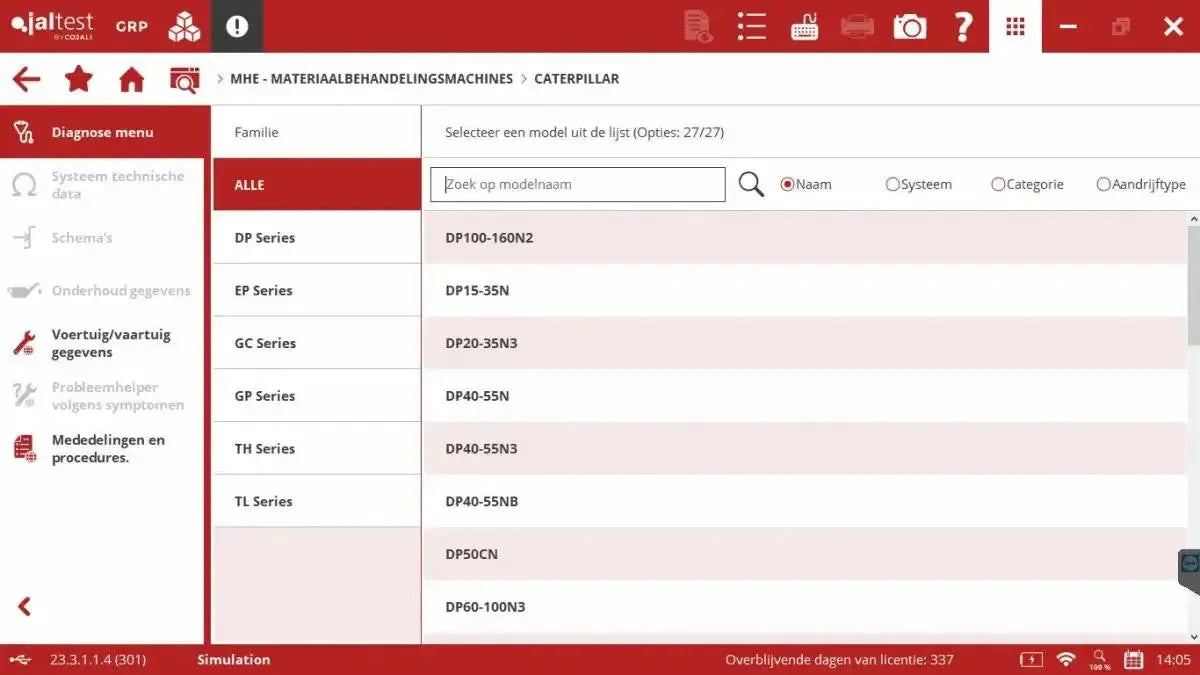

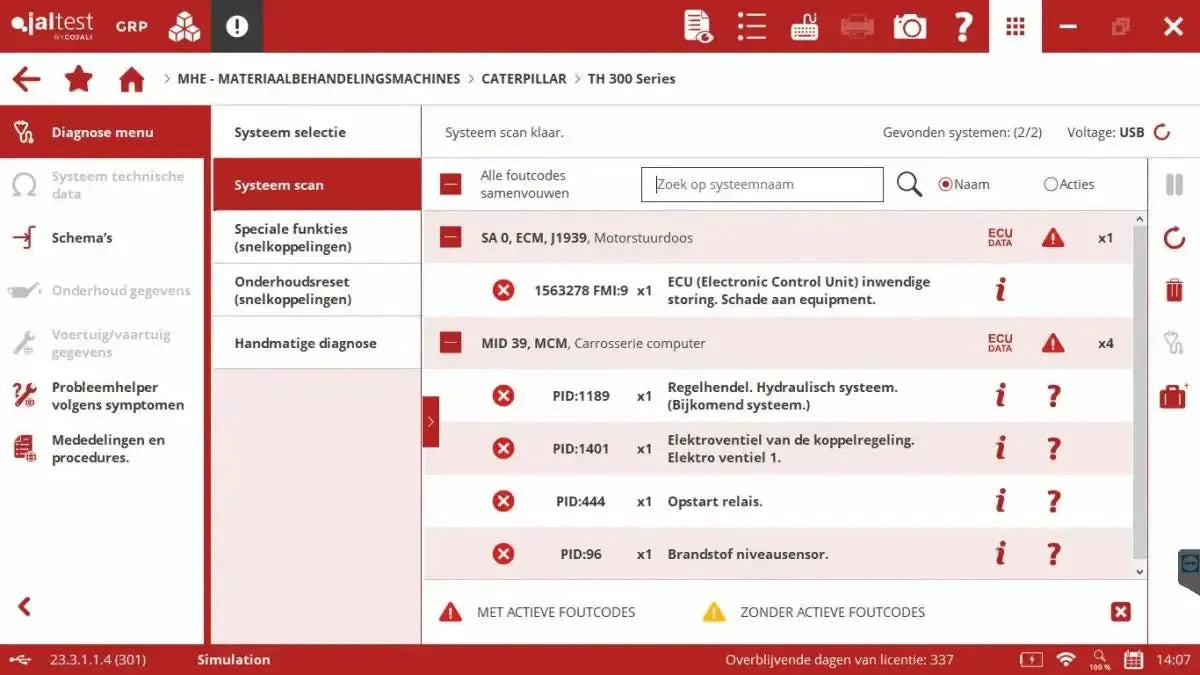

The Jaltest MHE (Material Handling Equipment) is a leading multi-brand and multi-system diagnostic platform, specifically developed for the complex electronics and hydraulics of internal transport equipment and lifting devices. The system supports a wide range of vehicles, including forklifts, telehandlers, aerial work platforms, and scissor lifts. The solution consists of the robust, wireless Jaltest Link VCI combined with the powerful Jaltest SOFT MHE diagnostic software.

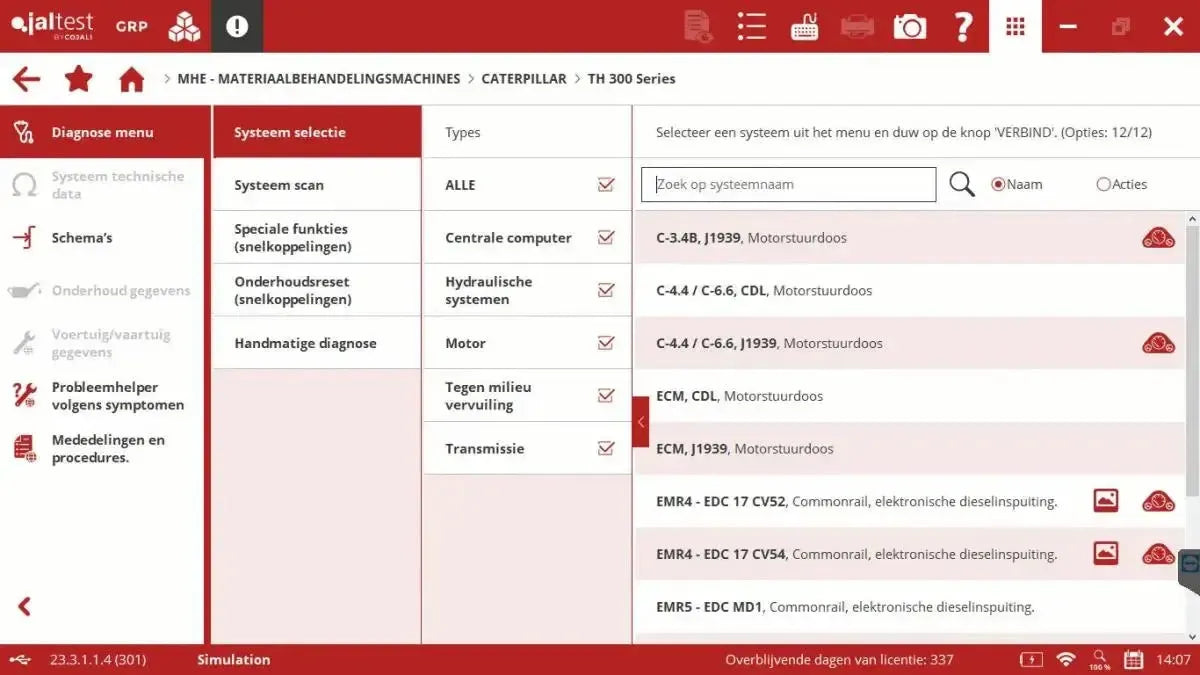

What sets Jaltest apart is the direct integration of diagnostics, technical information, and repair guidance in one working environment. The platform acts as a full-fledged technical workshop partner and supports the technician throughout the entire process – from detecting a hydraulic or electronic fault to the calibration after repair completion – all within an intuitive and clear interface.

Diagnostic functions:

The Jaltest MHE module offers comprehensive, brand-independent OE-level diagnostics for all electronic and hydraulic systems within internal transport equipment and lifting devices. This enables quick detection, analysis, and targeted resolution of faults.

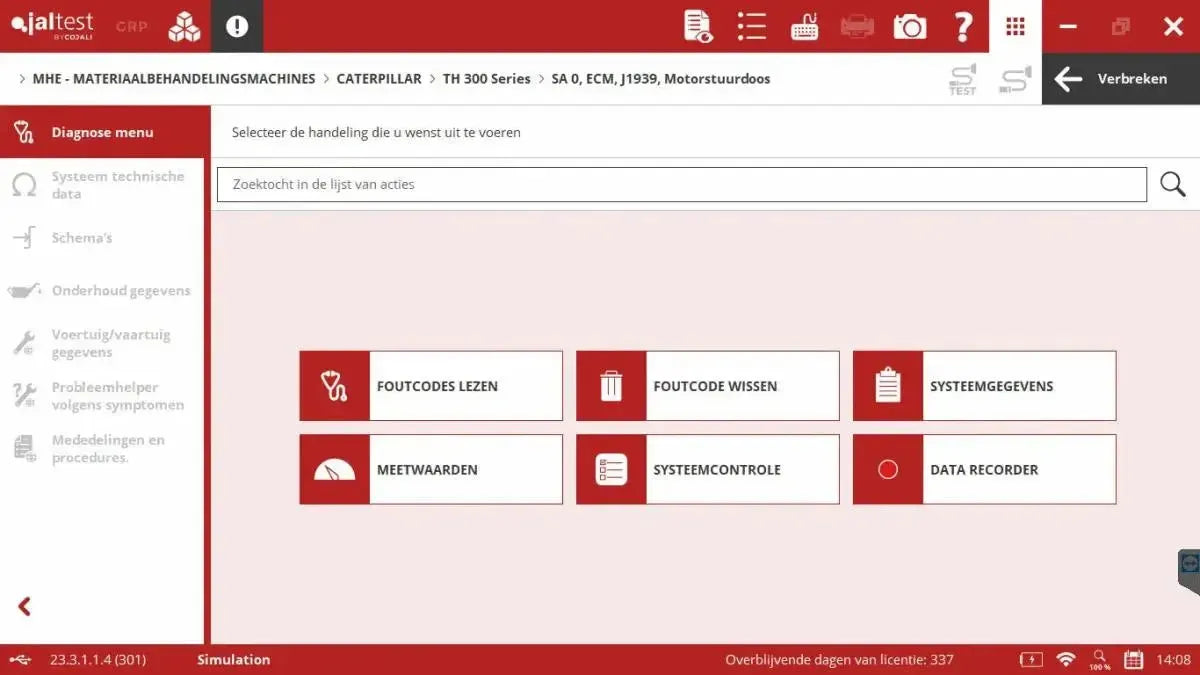

- Reading and clearing fault codes: Detects active, inactive, and permanent fault codes and displays corresponding descriptions. After repair, fault codes can be cleared immediately.

- Live data monitoring: Real-time display of sensor values and system parameters, such as hydraulic pressure, joystick positions, and engine speed. Values can be displayed numerically, in meters, or as an interactive graph. Users can make their own selections.

- Testing actuators: Direct control of components such as hydraulic valves, proportional valves, and engine speed controllers to verify the operation of subsystems in real time.

- System and ECU information: Access to important identification data of control units, including part number, software version, and serial number.

Maintenance, service, and calibration functions:

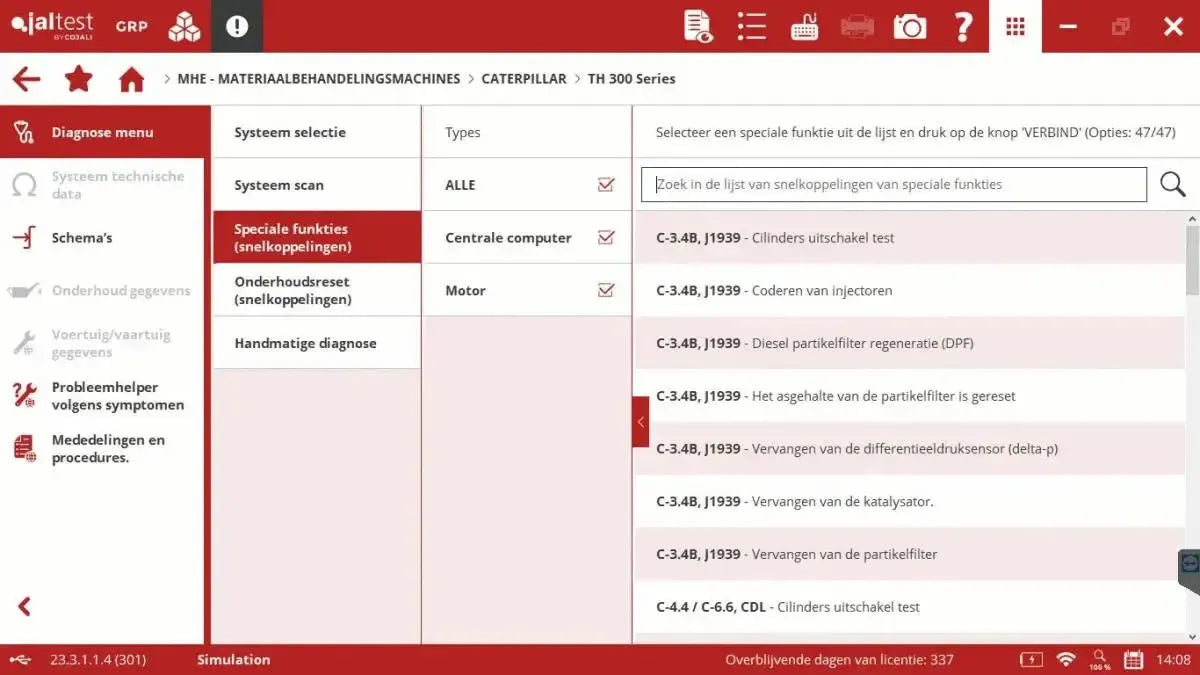

The Jaltest MHE (Material Handling Equipment) module offers an exceptionally wide range of maintenance, service, and calibration functions. These functionalities are designed for the complete management of maintenance, troubleshooting, and reconfiguration or commissioning of internal transport equipment, such as forklifts, reach trucks, aerial work platforms, and warehouse vehicles. The available functions match or exceed the capabilities of brand-specific diagnostic equipment, enabling technicians to professionally complete complex repairs from start to finish.

Engine-related functions:

- DPF service (diesel particulate filter): supports forced, static, and dynamic regeneration, including resetting soot and ash values after cleaning or replacing the filter.

- Oil and service interval reset: resets the maintenance indicator in the onboard computer based on operating hours or performed service.

- Injector coding: writes the unique calibration code of new or revised injectors to the ECU for optimal fuel injection and combustion.

- Engine condition tests: performs guided tests such as cylinder shutdown, compression tests, and checks of the variable geometry turbo (VGT).

- SCR/AdBlue system service: diagnosis and maintenance of the SCR system, including pressure measurements of the pump, injector checks, and resetting fault conditions.

Hydraulic functions:

-

Hydraulic calibration: precise adjustment of the hydraulic system, including:

- Proportional valves for lift, tilt, and drive functions

- Joystick and control lever calibration

- Sensor settings on mast, boom, or lift structure

- Maximum working pressures and flow rates

- Active hydraulic tests: direct control of valves, pumps, and sensors to detect faults at the component level.

Transmission and drive functions:

- Transmission calibration: adjusting hydrostatic and powershift transmissions for smooth and error-free driving behavior.

- Clutch learning: performing the learning procedure of the clutch after replacement or failure.

- Driving speed parameters: setting or adjusting the maximum driving speed where this is supported by the manufacturer.

Chassis and safety systems:

- Braking system service: diagnosis, calibration, and maintenance of electronic braking systems and components.

- Steering calibration: adjusting and reinitializing steering angle sensors and other parts of the control system.

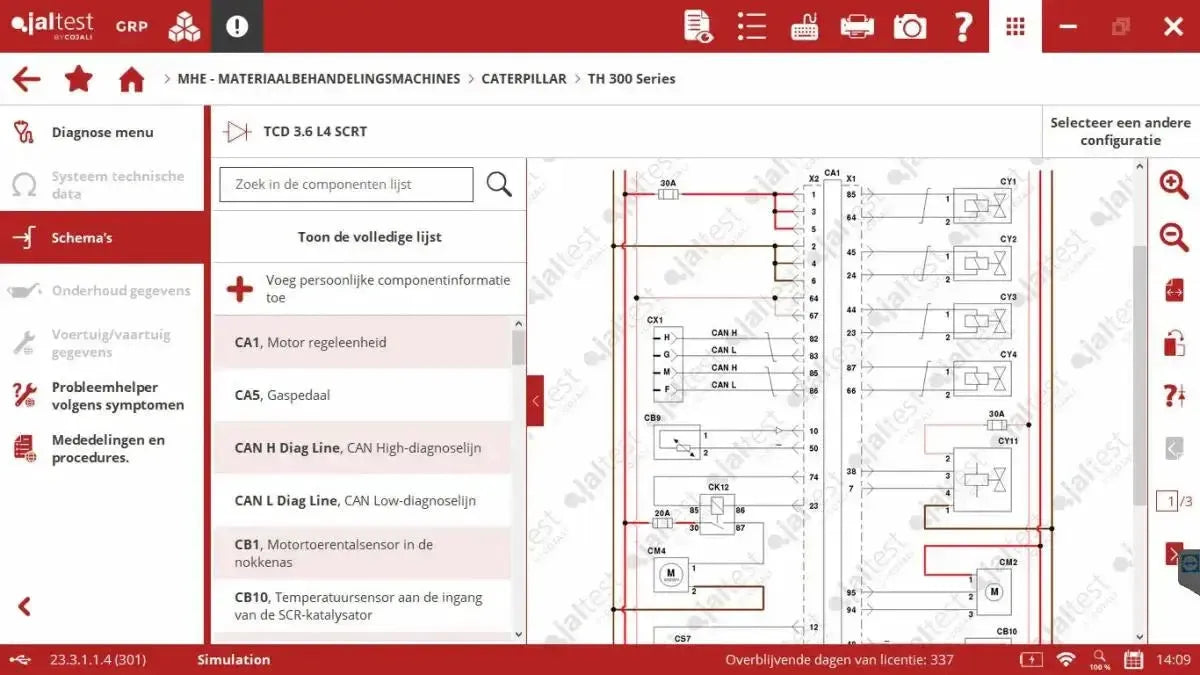

Advanced diagnostics & technical information:

The strength of the Jaltest MHE module lies in the direct integration of specialized technical information within the diagnostic software. This makes the platform not just a scanner, but a full-fledged technical partner for the MHE workshop.

-

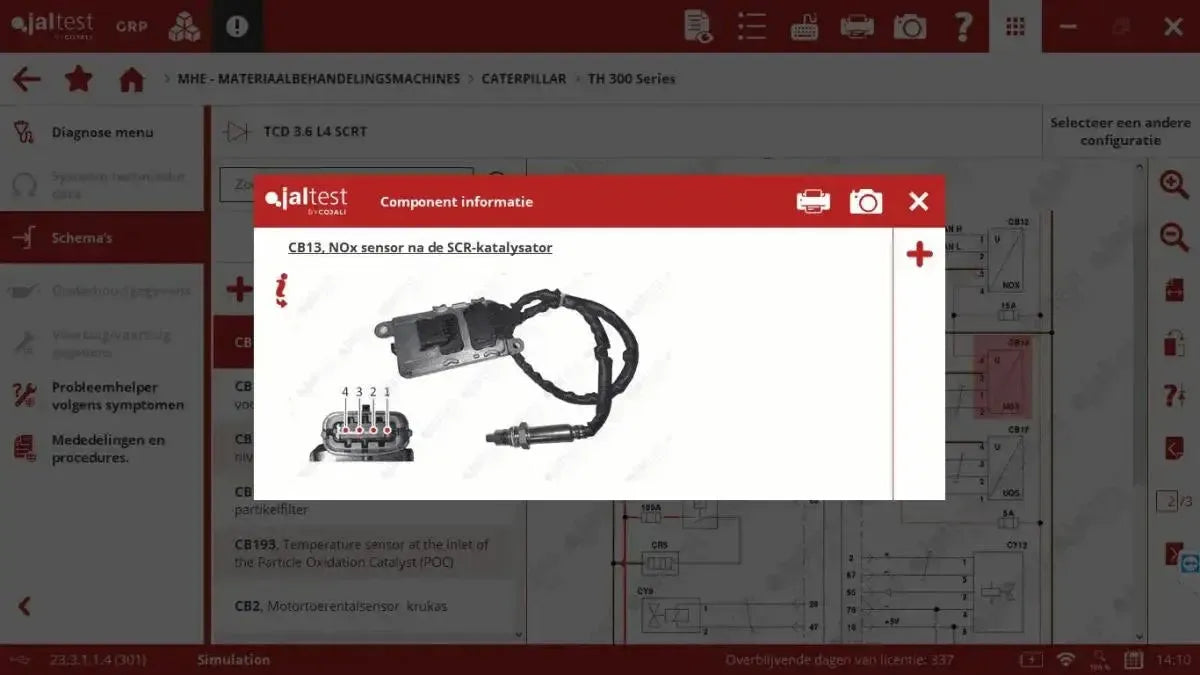

Interactive hydraulic and electrical diagrams: Fully clickable, dynamic diagrams in which components such as pumps, valves, sensors, fuses, and wiring can be explored interactively. Available data per component includes:

- Function and operation of the component

- Test procedures and nominal measurement values

- Component photos and location descriptions

- Pin-outs of connectors

-

Machine technical data: Jaltest contains extensive, vehicle-specific documentation, including:

- Tightening torques for engine and chassis components

- Hydraulic specifications, including pressure values, flows, and adjustments

- Fluid specifications for hydraulic oil, engine oil, coolant, and brake fluid

- Component data with technical details of, among others, pressure sensors, proportional valves, and ECUs

- Repair guides per error code: For each error code, Jaltest generates a step-by-step repair manual, including wiring checks, hydraulic line tests, component measurements, and concrete solutions per machine model.

- Symptom-based diagnosis: For complaints such as "does not lift", "drives slowly" or "engine smokes", guided diagnostic procedures can be initiated based on symptoms, without error code.

- Technical bulletins and procedures: Access to technical bulletins issued by Jaltest, focused on common defects, known issues, and specific repair advice for MHE machines.

- Maintenance data: Automatically generated maintenance schedules based on operating hours, including prescribed intervals and detailed work lists.

- Service procedures: Clear step-by-step instructions for performing all maintenance and service tasks, including required parts, fluids, and adjustment values.

Specialized software modules:

The Jaltest MHE module is part of a modular ecosystem and can be expanded with specialized software solutions that significantly improve efficiency, documentation, and testing capabilities within the workshop:

- Jaltest GRP (Garage Resource Planning): An integrated workshop management system that allows users to manage customers, vehicles, work orders, and maintenance scheduling. Diagnostic reports are automatically linked to the corresponding work order, ensuring a structured and complete administration.

- Jaltest ETM (Electronic Test Module): In combination with optional ETM hardware, electronic components such as sensors, joysticks, actuators, and hydraulic modules can be tested outside the vehicle. This is particularly useful for checking components with uncertain operation or after replacement.

- Jaltest Info Online: A digital technical knowledge base with direct access to repair manuals, error code explanations, electrical diagrams, hydraulic diagrams, technical bulletins and more. Everything is linked to the brand, model, and system, and fully integrated into the Jaltest diagnostic environment.

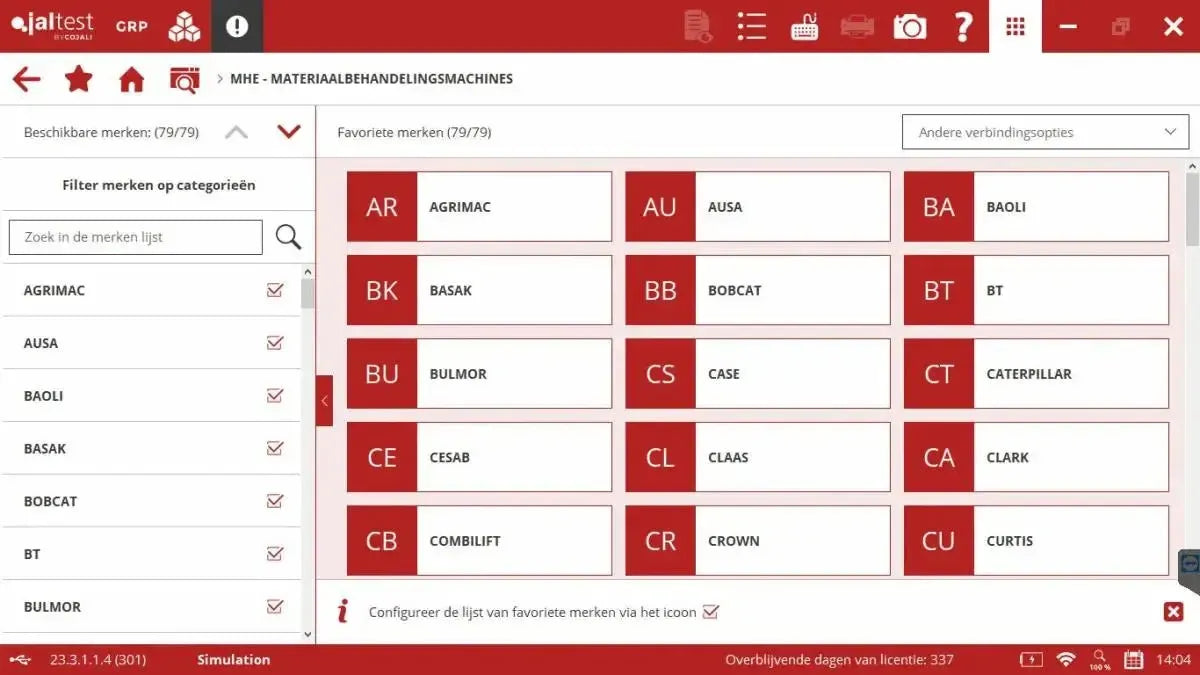

Supported vehicle brands:

- Material handling machines: Agrimac, Ausa, Baoli, Basak, Bobcat, BT, Bulmor, Case, Caterpillar, Cesab, Claas, Clark, Combilift, Crown, Curtis, CVS Ferrari, Deutz-Fahr, Dieci, Donkey, Doosan, EuroYen, Faresin, Gehl, Genie, Giant, Hangcha, Harlo, Haulotte, Heli, Hoist, Holland Lift, Hyster, Hyundai CE, JCB, JLG, John Deere, Jungheinrich, Kalmar, Konecranes, Kramer, Kubota, LGMG, Liebherr, Liftking, Linde, LiuGong, Magni, Manitou, Massey Ferguson, MB, Merlo, Mitsubishi, Moffett, New Holland, Nissan, OTO, Paus, Pettibone, Princeton, Sany, Sellick, Sennebogen, SkyJack, SkyTrak, Snorkel, Still, Taylor, TCM, Terex, Thaler, Toyota, Unicarriers, Wacker Neuson, Weidemann, XCMG, Xtreme, Yale, Zapi, Zoomlion

Package contents:

- Jaltest Link V9 Interface

- Jaltest 15 Pins DB15 - 16 Pins OBD2 Adapter Plug

- Jaltest 26 Pins DB26 Extension Cable

- Jaltest USB-A - USB-B

- Jaltest Multi-pin Kit

- Jaltest Storage Case (Compact)

- Jaltest Cigarette Lighter Adapter Cable

License information:

The Jaltest MHE module operates based on an annual software license. This license provides full access to all diagnostic, maintenance, and calibration functions for forklifts, reach trucks, warehouse trucks, and other internal transport equipment within the material handling segment. The license includes:

- Three major software updates per year, with improved brand and model coverage, new functionalities, and up-to-date technical information.

- Access to technical support, including assistance with activations, diagnostic procedures, software updates, and interpretation of error codes and parameters.

Modular structure:

The Jaltest software is modularly expandable. In addition to Material Handling Equipment (MHE), additional licenses can be activated for other vehicle categories, such as:

-

Commercial vehicles (CV)

- Off-Highway machines (OHW)

- Agricultural vehicles (AGV)

- Maritime applications (Marine)

Technical specifications

| Specification | Details |

|---|---|

| Connectivity | Bluetooth 5.0, USB |

| Supported protocols | ISO 9141‑2, ISO 14230, ISO 15765, SAE J1708, J1939, J1850, RP1210, J2534 (Pass-Thru), CAN FD |

| Power supply | 8–32V via vehicle diagnostic connector |

| Housing | Shock-resistant design, IP40 dust and splash water resistant |

| Indicators | Multicolor LEDs for status indication |

| Dimensions | Compact and lightweight design (±76% lighter than Jaltest V8) |

| Connections | SUBD-26 connector (vehicle side), USB type B (PC side) |

| Operating temperature | -10°C to 60°C |

| Storage temperature | -20°C to 70°C |

To ensure that you always have access to the latest updates and software for your Jaltest device, it is important that you register the correct distributor.

Only the registered distributor can perform new software and updates. When you appoint us as your distributor, we can take care of this for you and guarantee that your device remains up-to-date without any issues.

How does it work?

-

Download and fill in the change form

You can find the form as a PDF file here. -

Send the completed form to us

This can easily be done by email to support@astools.eu. -

We take care of the rest

With the form, we at Jaltest can submit the change and officially register you as our customer.